How Vapor-Static Extraction is Revolutionizing Cannabis and Hemp Processing Technology

Mini blog - 4 minute read

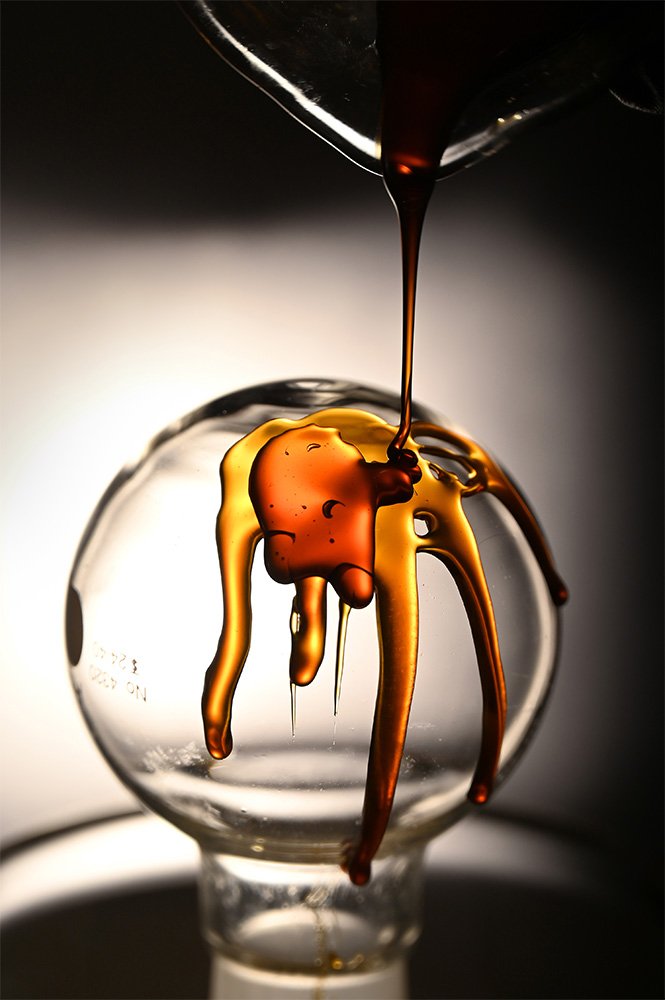

The heart of innovation is the drive to do more with less. In the world of cannabis and hemp extraction, no methods existed until recently that were both legitimately sustainable in terms of the resources consumed while also possessing the ability to scale production commercially with rapidly growing industry demand. At present the vast majority of THC and CBD concentrates, edibles, vaporizers, tinctures, as well as many other niche products are made using fossil fuel-derived chemical solvents such as ethanol or butane. That is poised to change however with the recent invention of Vapor-Static cannabinoid extraction, which requires a fraction of the electricity, water, and manpower other large scale oil processing machinery need to operate. Vapor-Static extraction technology, which is being pioneered by Boulder Creek Technologies, utilizes the application of highly specialized electrostatic precipitators that efficiently collect crude cannabis or hemp oil using only water and electricity. Electrostatic precipitators are commonly used to remove soot and ash from coal-fired power plants or other harmful gasses at cement factories, but have just recently been successfully engineered for use in cannabinoid extraction after years of research and development.

Comparatively, existing industrial scale solvent-based extraction systems use enormous amounts of electricity in addition to highly refined fossil fuels, whereas Vapor-Static uses no solvents whatsoever and significantly less power. From the standpoint of environmental stewardship juxtaposed with the reality of enormous future product demand in one of the world’s fastest growing industries, current solvent-based processing techniques present real concerns. The fundamental difference with the use of Vapor-Static technology instead of solvents to create cannabis or hemp oil is that cannabinoids can be captured without having to be dissolved in harsh pressurized or flammable chemicals. Instead, with Vapor-Static, THC or CBD are condensed and captured from a non-coalescing fog that the system creates. Further still, spent plant matter that has been processed with Vapor-Static can be safely composted into a high quality soil amendment fertilizer. Solvent-processed plant matter however ends up saturated with unrecyclable chemicals and must be carefully disposed of – these kinds of spent biomass offer no downstream waste recycling opportunities. Vapor-Static technology presents enormous opportunities for licensed businesses to meet increased consumer demand while meaningfully reducing their environmental impact and resource consumption to do so.

Even though cannabis and hemp production is just one facet of commercial agriculture across the globe, they combine to represent a massive amount of new and upcoming business activity. According to Allied Market Research, the global marijuana market could grow to become nearly a $150 billion dollar a year industry by 2030. Another report indicates that the global hemp market could reach over $17 billion in the same time period (by 2030), which together demonstrates the pressing need for sustainable extraction technologies that can run entirely off of renewable resources. It isn’t controversial to expect that the vast majority of these businesses will not adopt sustainable practices unless there is a cost or profit incentive to do so or such things are at the heart of their company’s values. That’s where Boulder Creek Technologies and its patented Vapor-Static extraction systems come in. Vapor-Static sits at the bullseye of sustainable processing and ongoing industrial-scale innovation that makes financial sense for operators. As more and more businesses seek strong growth while minimizing their environmental impacts, Vapor-Static is likely to replace much of the existing bulk cannabinoid processing market’s existing solvent systems.